Description

Mayur Straps – Trusted LDPE Pipe Supplier

Low-density polyethylene (LDPE) is a thermoplastic made from the monomer ethylene. It was first created in 1933 by Dr. John C. Swallow and M.W. Perrin at Imperial Chemical Industries (ICI) through a high-pressure free-radical polymerization process. This method remains in use even today. LDPE continues to play an important role in the plastic industry despite the rise of modern polymers. The EPA states that the United States recycles around 5.7% of LDPE (resin code 4). In 2013, the LDPE market touched a global value of nearly US $33 billion. Unlike HDPE, LDPE molecules bend and entangle easily, giving the material excellent flexibility.

High-Quality LDPE Pipes for Multiple Applications

As a leading LDPE Pipe Supplier, Mayur Straps delivers pipes made from premium-grade polyethylene. Our pipes are lightweight, strong, and easy to install. Their flexibility allows them to bend and follow the natural layout of your site without extra fittings. This feature helps reduce installation time and overall project cost. Our LDPE pipes also resist cracking, corrosion, and abrasion, making them ideal for transporting water, chemicals, and other liquids across different environments.

Reliable Imported Polymers for Industry Needs

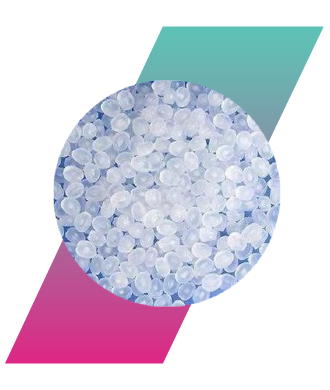

We source imported polymers from reputable global suppliers to match the needs of industries that rely on high-performance plastics. These polymers support a wide range of applications, including packaging, automotive parts, construction materials, electronics, and medical products. By working with trusted international manufacturers, we ensure that our customers receive top-quality materials for their operations.

Benefits of Using Imported Polymers

Imported polymers meet rigorous quality standards and industry regulations. Many of these materials use advanced manufacturing technologies that offer excellent impact resistance, chemical resistance, and thermal stability. These features make them suitable for demanding applications such as food packaging, automotive manufacturing, medical devices, and electronic components. At Mayur Straps, we supply these polymers to help businesses achieve reliable performance and long-lasting results.

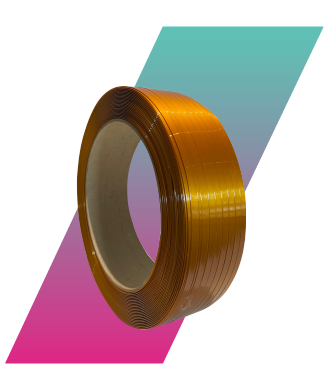

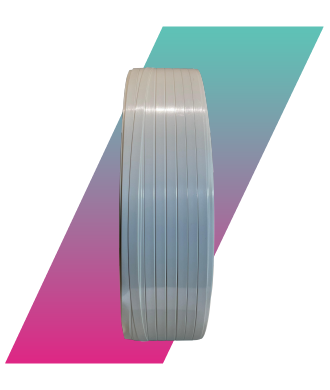

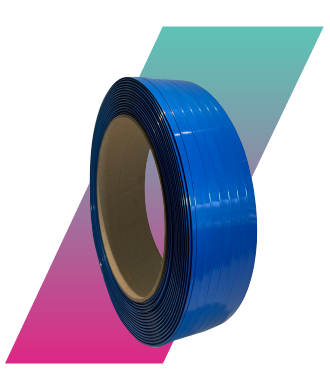

We Provide strapping material like PET Strap, PET Band, Polyester Strap, Polyester Band, Packing Strap, Pet Strap Roll, High Tension Strap, Cut Size Pet Strap, Heavy Load Strap, Plastic Strap, Chemical Resistance Strap, Pet Box Strap and PP Strapping. We also Provide the Import Polymers like PET Chips, Polypropylene, PVC, HDPE, LDPE, LLDPE, Others. For Strapping Tools We have Pneumatic, Digital Power, Digital Smart, Poli Welding Tool and Manual Packaging Tool.