Description

Mayur Straps is a leading PET Chips Manufacturer. Polyethylene Terephthalate (PET) chips serve as the basic material for plastics and polymers. Depending on processing, PET exists as shapeless (transparent) chips, commonly known as Bright or Super Bright Chips, or as semi-crystalline PET Semi-Dull Chips. We also provide other imported polymers.

PET chips act as the primary raw material for producing PET bottles, containers, films, and polyester fibers in the textile industry. Our PET chips offer exceptional clarity, strong chemical resistance, and high durability, making them suitable for demanding applications. They maintain consistent quality and uniformity, ensuring smooth and efficient production in downstream processes.

We produce PET chips by granulating polyester obtained from the polycondensation of pure terephthalic acid and ethylene glycol. Industries rely on our PET chips to create high-quality PET films and fibers in semi-dull, full-dull, and super-bright finishes.

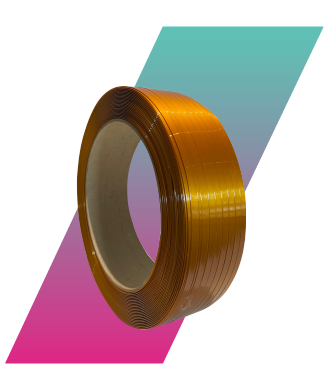

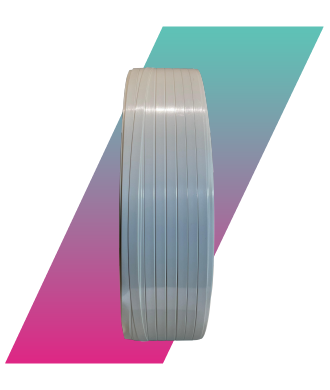

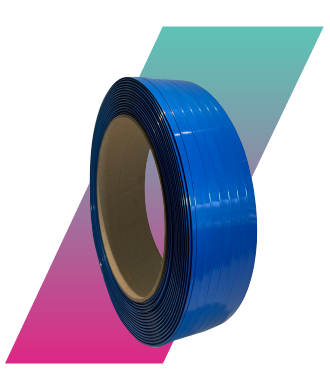

We Provide strapping material like PET Strap, PET Band, Polyester Strap, Polyester Band, Packing Strap, Pet Strap Roll, High Tension Strap, Cut Size Pet Strap, Heavy Load Strap, Plastic Strap, Chemical Resistance Strap, Pet Box Strap and PP Strapping. We also Provide the Import Polymers like PET Chips, Polypropylene, PVC, HDPE, LDPE, LLDPE, Others. For Strapping Tools We have Pneumatic, Digital Power, Digital Smart, Poli Welding Tool and Manual Packaging Tool.